Gas shielded welding wire is divided into two categories: solid core welding wire and flux core welding wire. In China, solid core welding wire is currently mainly used, but flux core welding wire is rapidly being promoted and has broad application prospects.

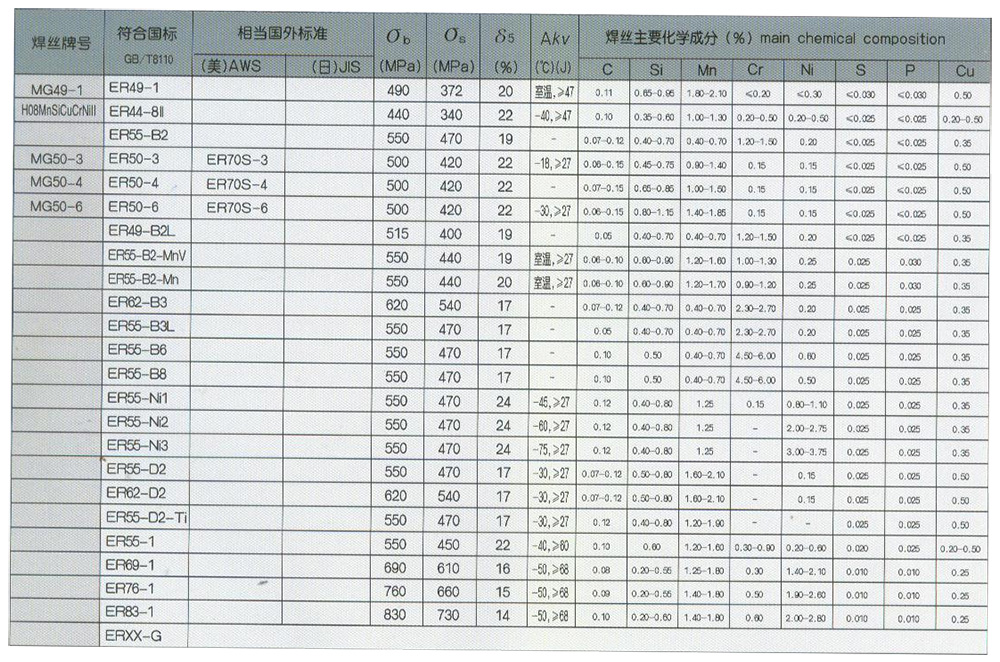

Special welding wire for gas shielded arc welding. According to different manufacturing methods, it can also be divided into two categories: solid core welding wire and flux core welding wire. In China, solid core welding wire is currently mainly used, but flux core welding wire is rapidly being promoted and has broad application prospects. In Japan, the usage of solid core welding wire is still greater than that of flux cored welding wire, but there are more varieties of flux cored welding wire, including various welding wires for carbon steel, low alloy high-strength steel, low-temperature steel, heat-resistant steel, and stainless steel, as well as various flux cored welding wires suitable for overlay welding. According to different welding methods and shielding gases, it can be divided into TIG welding wire, MIG welding wire, and mag welding wire. TIG welding wire is used in conjunction with pure Ar as a shielding gas, and the composition of the welding wire is similar to that of the weld seam. MIG welding wire, combined with Ar+2% O2 or Ar+5% CO2 shielding gas, is mainly used for welding high alloy steels such as stainless steel. MAG welding wire can be used in conjunction with Ar adding more than 5% CO2 or Ar adding more than 2% O2 shielding gas, or 100% CO2 can be used as the shielding gas. The latter type of protective gas has a low cost and is widely used for welding carbon steel, low alloy steel, stainless steel, etc. It can also be used for overlay welding. With the increase of CO2 or O2 content in the protective gas, the oxidation of the arc atmosphere is enhanced, and it is required that the welding wire should contain sufficient amounts of deoxidizers, such as silicon, manganese, etc.

Tel

+86-533-6412127 6451635