Nickel and nickel alloy welding rods refer to those mainly used for welding pure nickel and high nickel alloys. Sometimes it is also used for welding dissimilar metals. However, considering the alloy loss of the welding rod in the arc, other elements should also be included in the welding rod to improve the performance of the weld or welding process.

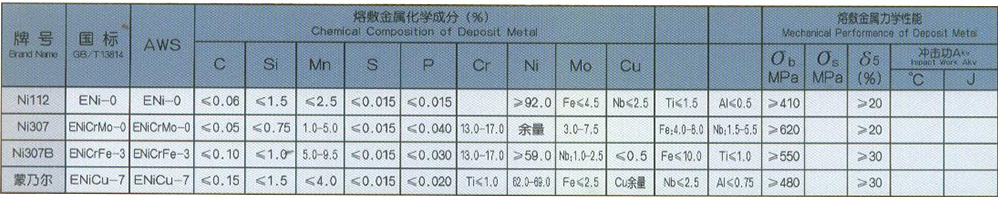

(1) The selection principles of nickel and nickel alloy welding rods are mainly based on the alloy grade, chemical composition, and usage environment of the base material being welded. The main chemical composition of the deposited metal of the welding rod should be close to the main composition of the base metal to ensure that the various properties of the welded joint are equivalent to those of the base metal. However, considering the alloy loss of the welding rod in the arc, other elements should also be included in the welding rod to improve the performance of the weld or welding process.

If the use of welding rods with the same composition cannot meet the design requirements or there is no suitable welding rod with similar alloy composition, it is recommended to choose welding rods with higher performance to ensure that the performance of the weld seam is not lower than that of the base material.

(2) Precautions for the use of nickel and nickel alloy welding rods

① Preparation of base material: Before welding, the surface of the base material should be carefully cleaned of dirt such as oil, paint, and dust.

② To prevent porosity, short arc welding is used.

③ Using a smaller welding current, without preheating before welding, maintain a lower interpass temperature (<150 ℃) to avoid overheating of the base material.

④ When welding, the swinging amplitude of the welding rod should be small, and the two sides of the weld bead should stay for a slightly longer time to facilitate the floating of air holes and welding slag.

⑤ When closing the arc, pay attention to filling the arc crater to prevent the occurrence of arc crater cracks.

⑥ The microstructure of nickel and nickel alloys is austenitic, with a strong tendency towards hot cracking. When welding corner welds, it is required that the weld bead be convex, which can effectively prevent the occurrence of hot cracking.

Tel

+86-533-6412127 6451635