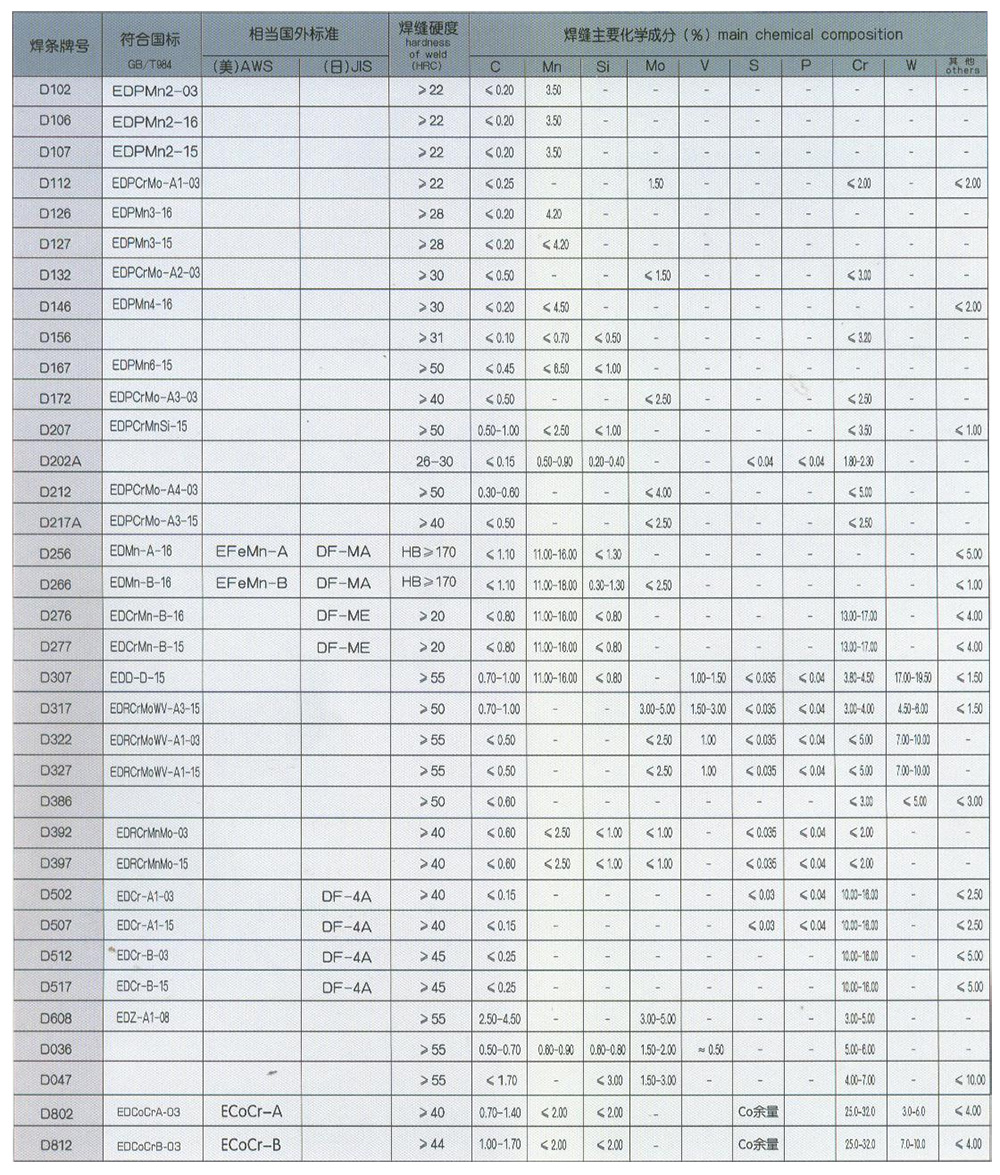

Surfacing welding rod refers to a special alloy surface used to weld any part of the workpiece, with the aim of improving the wear resistance, corrosion resistance, and heat resistance of the working surface, reducing costs, and improving comprehensive performance and service life. Overlay welding is also commonly used for repairing old and recycling waste. When welding, different alloys and hardness levels of welding rods are generally selected according to the usage requirements. The purpose of overlay welding is to deposit a special layer of alloy on the surface of the workpiece to improve its wear resistance, corrosion resistance, or heat resistance. In actual production, the usage conditions of overlay welding workpieces are very complex. Therefore, when overlay welding, it is of great practical significance to choose the appropriate welding rod that is suitable for the workpiece usage conditions.

Overlay welding is also commonly used for repairing old and recycling waste When welding, different alloys and hardness levels of welding rods are generally selected according to the usage requirements.

Tel

+86-533-6412127 6451635