Stainless steel welding rod refers to a type of welding rod coated with stainless steel as the source material. It can be divided into chromium stainless steel welding rods and chromium nickel stainless steel welding rods, widely used in industries such as chemical, fertilizer, petroleum, and medical machinery manufacturing.

Rust steel welding rods should not only meet the general welding process performance and mechanical properties of welding joints, but also ensure that the welding joints can meet certain corrosion resistance requirements. For the coating and solder core, the following requirements are usually considered:

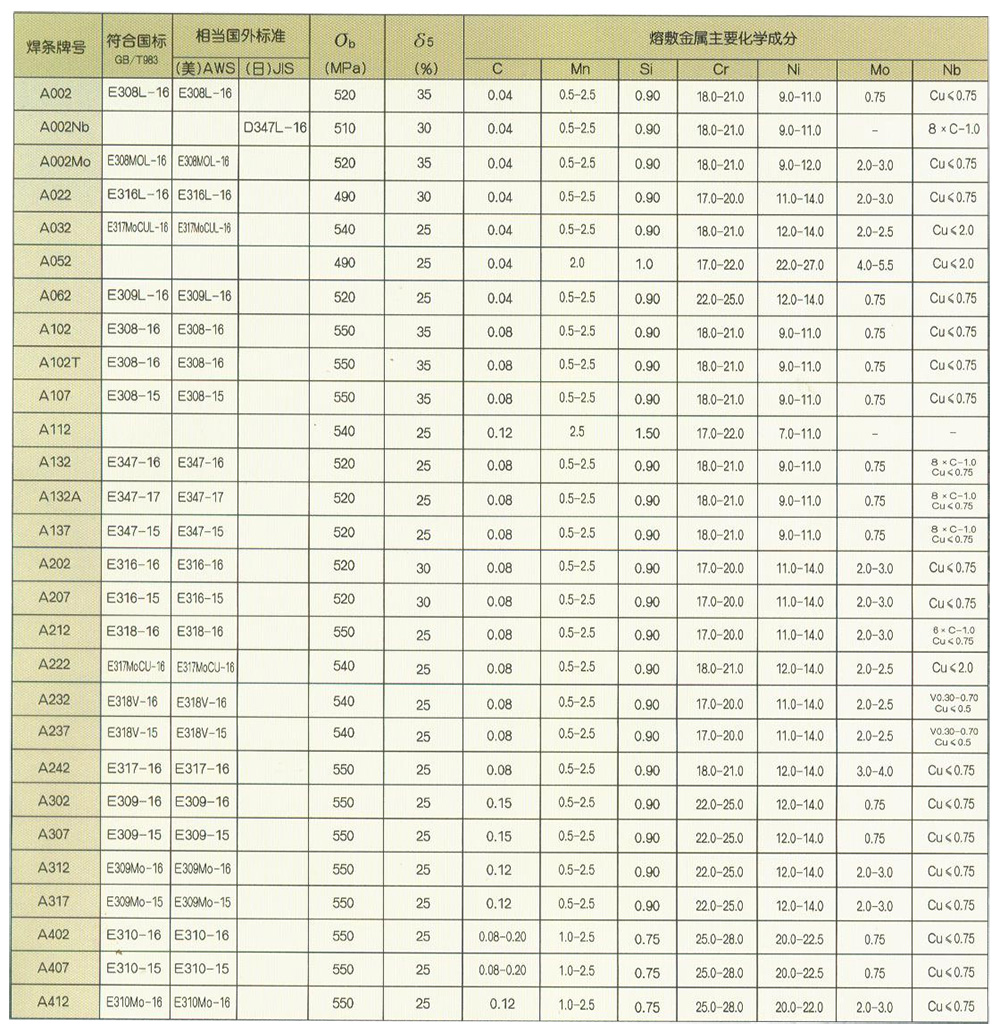

1) By transitioning various alloy elements through the welding core and coating, the weld metal is made into a structure containing a certain amount of austenite and ferrite, ensuring that the weld metal has both good crack resistance and the ability to resist corrosion from corresponding media.

2) By using a welding core or coating, a certain amount of carbide forming elements (such as niobium, molybdenum, titanium, etc.) can penetrate into the weld metal, forming stable carbides with carbon to prevent the formation of chromium carbides at grain boundaries.

3) The increase of carbon will promote intergranular corrosion in austenitic stainless steel (or ferritic stainless steel) welds. Therefore, the carbon content in the raw materials of the welding core and coating should be strictly controlled. It is recommended to use low-carbon or ultra-low-carbon welding cores, and use low-carbon or non carbon iron alloys and metallographic elements as raw materials for the coating.

4) Strictly control the sulfur and phosphorus content in stainless steel welding cores and coatings to reduce the risk of weld thermal cracking.

Tel

+86-533-6412127 6451635